Direct Shear Test

Overview

The Direct Shear Test is is one of the most widely used laboratory tests to determine the shear strength of soil, rock, and other materials. This test can be performed under drained or undrained conditions with rock, soil, or asphalt samples. Shear strength is an extremely important property to attain in the field of geotechnical engineering as it is often required to determine the response of a soil to construction, earthquakes, and more. In this test, the results are attained by deforming a specimen at a controlled strain rate on or near a single shear failure plane. The test results, when analyzed using a Mohr-Coulomb Failure Envelope, allow the cohesion and angle of internal friction to be determined, which are needed when calculating the usefullness of a soil or rock as a foundation or backfill material. This test is comparable to the Simple Shear Test or the Triaxial Test, as these tests can also be used to calculate the shear strength of a soil.

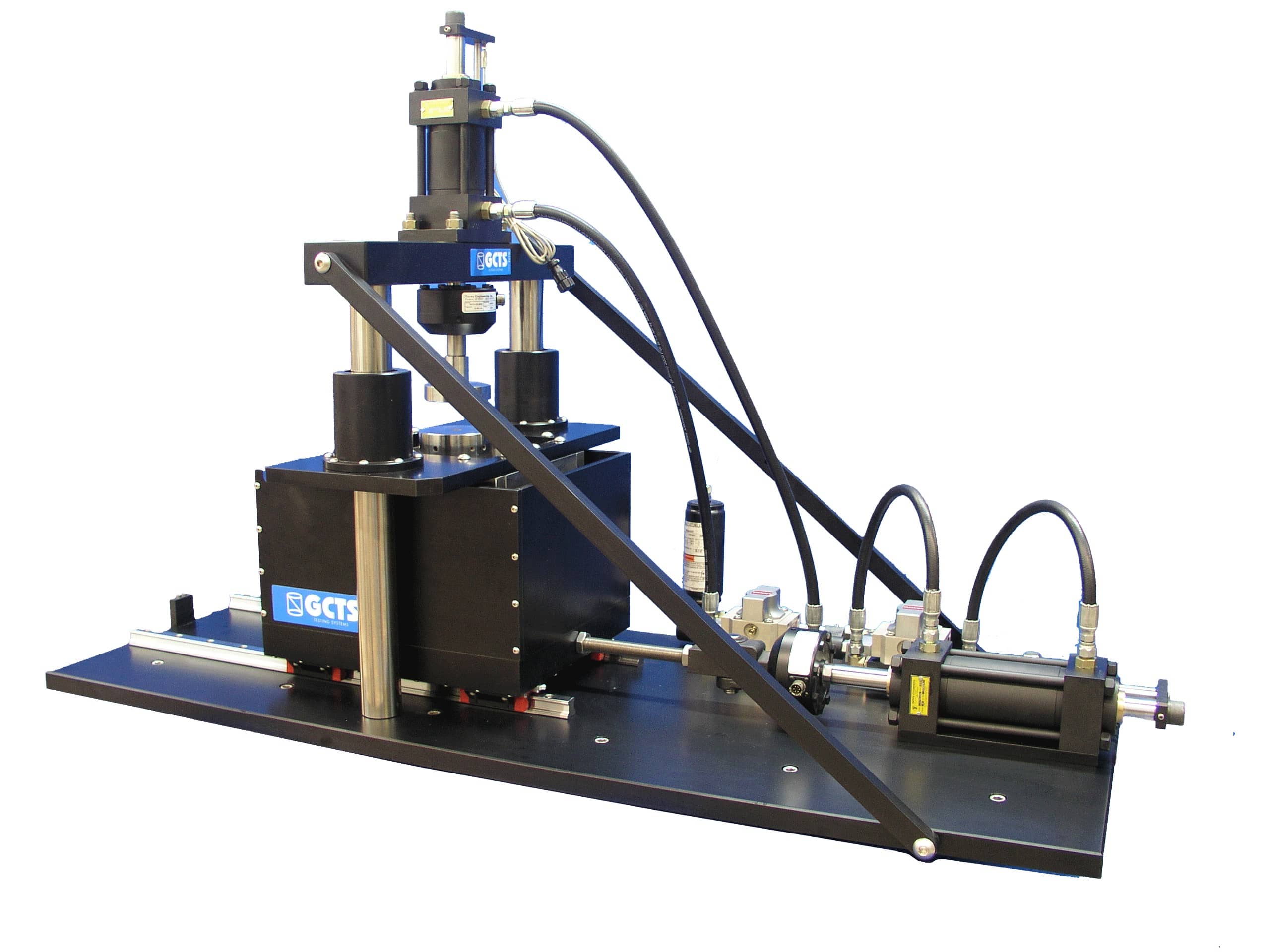

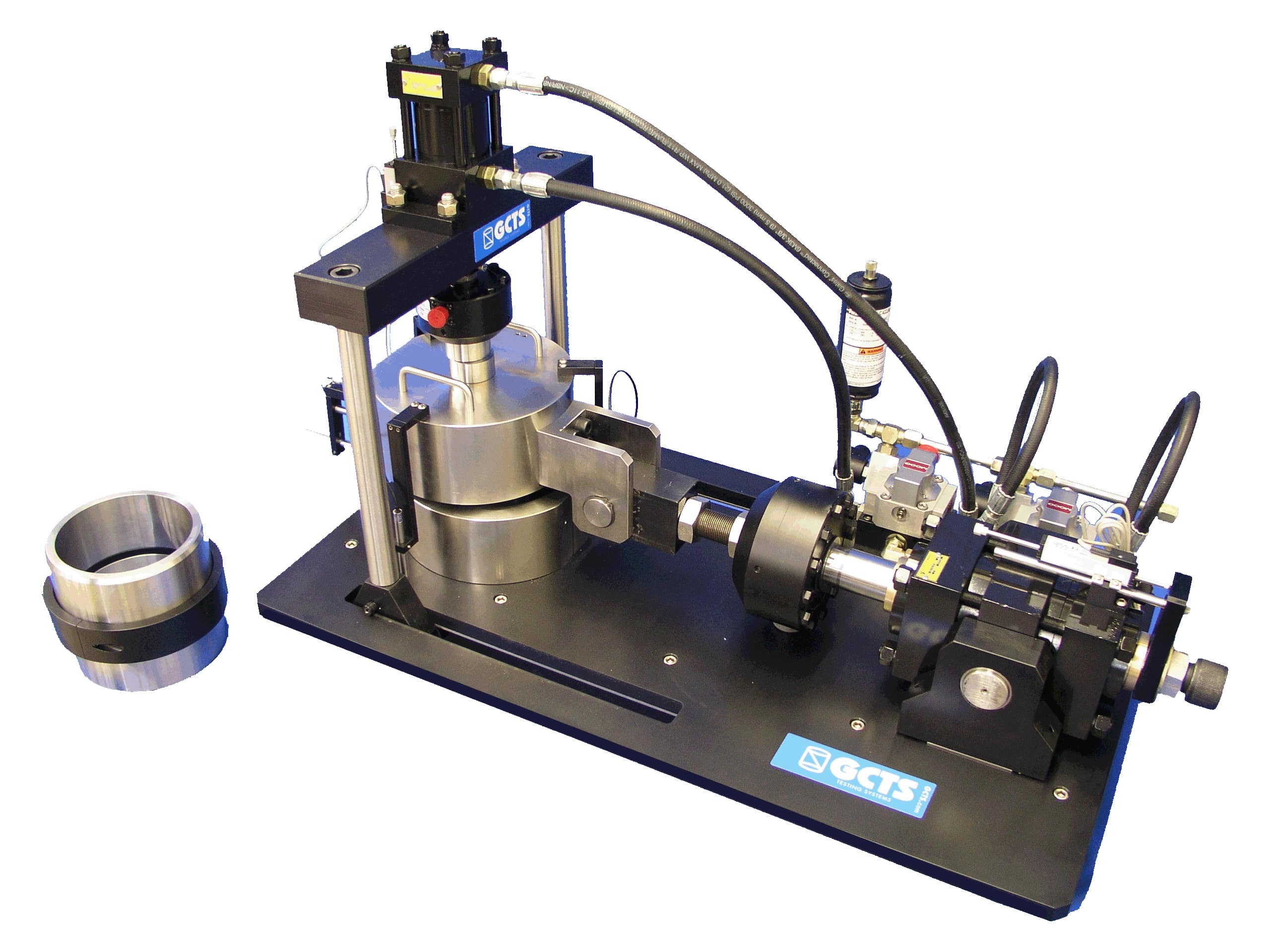

Direct Shear Testing Equipment (Courtesy of GCTS)

How is a Direct Shear Test Performed?

A specimen is placed in a shear box, which contains two stacked rings that hold the specimen in place. The two rings should meet approximately in the center of the specimen, so that one half of the specimen is in the top of the shear box and the other half of the specimen is in the bottom of the shear box. A confining stress is then slowly and vertically applied to the specimen, giving the specimen time to consolidate. This means that water in the specimen will be squeezed out of the specimen prior to shearing. Once the specimen has been consolidated, the upper shear ring is pulled laterally at a constant rate of deformation while the axial load is kept constant until the specimen exhibits failure or until a pre-specified deformation limit is reached. Multiple specimens should be tested at varying confining stresses in order to find the shear strength parameters, the cohesion (c), and the angle of internal friction (φ).

This test can be performed under undrained or drained conditions. In the undrained condition, water in the specimen after consolidation is not allowed to leave the test specimen during shearing. The drained condition, however, does allow water to leave the test specimen during shearing.

What do Direct Shear Test Specimens Look Like?

Specimen preparation and dimensions differ between direct shear tests for soils and direct shear tests for rocks. In both, however, a carefully controlled environment should be used.

Test Specimens for Soils

In order to attain the best test data, a single large sample of soil should be used to create three specimens. The specimens should be prepared in a controlled environment such that the temperature and humidity are constant in order to minimize moisture loss or gain. As required by the ASTM standards, the minimum specimen diameter for circular specimens should be 50 mm (2.0 in.) or at least 10 times the diameter of the largest particle, whichever is larger. The diameter must also be at least twice the thickness of the specimen.

The initial specimen thickness should be a minimum of 12 mm (0.5 in.), but not less than six times the diameter of the largest particle.

Test Specimens for Rocks

In order to attain the best rock specimen, care should be used in core drilling, handling, and sawing in order to prevent mechanical damage to test specimen. No liquids other than water should come into contact with a test specimen. The height of a rock test specimen should be greater than the thickness of the shear (test) zone and large enough to embed the specimen in the holding rings. Specimens in a rock direct shear test can be of any shape as long as the cross-sectional areas can be readily determined. In the majority of cases, the least cross-sectional dimension of the test specimen should be at least 10 times the largest grain size within the specimen. The testing plane of the specimen should bear a minimum area of 1900 mm2 (3 in.2).

How are Specimen Characteristics Determined?

The cohesion and the angle of internal friction of a sample can be determined from an analysis of the Mohr-Coulomb Failure envelope. For more information on the determination of specimen characteristics, click here.

What are the Trade-Offs of the Direct Shear Test?

The direct shear test is a relatively quick and inexpensive test that can easily be used to determine the cohesion and angle of internal friction of a sample. However, due to the nature of the testing equipment, only approximations of these parameters can be determined. During this test, the failure plane of the specimen is forced to be horizontal (where the shear boxes meet), so failure may not occur on the weakest plane. During the test, there is no way to control the stress path, or way the specimen goes from one state of stress to another. Also, this test does not allow for the calculation of a stress-strain curve, as the height of the specimen is free to change during the test. Due to these factors, the direct shear test is a simpler, but less accurate test than a triaxial test.

Keywords: Shear — Direct Shear — Stress — Shear Stress — Angle of Internal Friction — Cohesion — Shear Strength — Confining Stress — Direct Shear Testing Equipment — Direct Shear Testing System — Direct Shear Test — Direct Shear Tester — Mohr Strength Envelope

© 2016 Geotechnical Consulting and Testing Systems, LLC. All Rights Reserved.

- ASTM D5607 - Rock Direct Shear Test Standard

- ASTM D4554 - In Situ Determination of Direct Shear Strength of Rock Discontinuities

- ISRM Determination of the Shear Strength of Rock Joints

- ASTM D3080 - Soil Direct Shear Test Standard

- ASTM D5321 - Shear Strength by Direct Shear of Soil Materials

- ASTM D6528 - Consolidated Undrained Direct Simple Shear of Cohesive Soils

- AASHTO T236 - Direct Shear Test of Soils Under Consolidated Drained Conditions

Rock Standards

Soil Standards